Environmental Management System

Environmental Management System

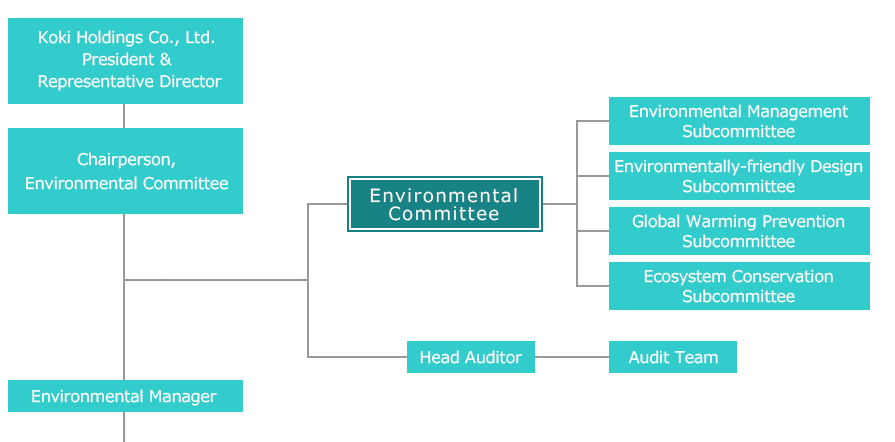

The Koki Holdings Group, including its overseas plants, implement environmental management systems. At the center of this system is the Environmental Committee, whose members include representatives not just of the manufacturing units, but group companies such as Sankyo Diamond Industrial Co. Decisions made by the Committee are communicated to overseas plants, including Fujian Hikoki and Guang Dong Hikoki.

Environmental Management System (as of May 2021)

|

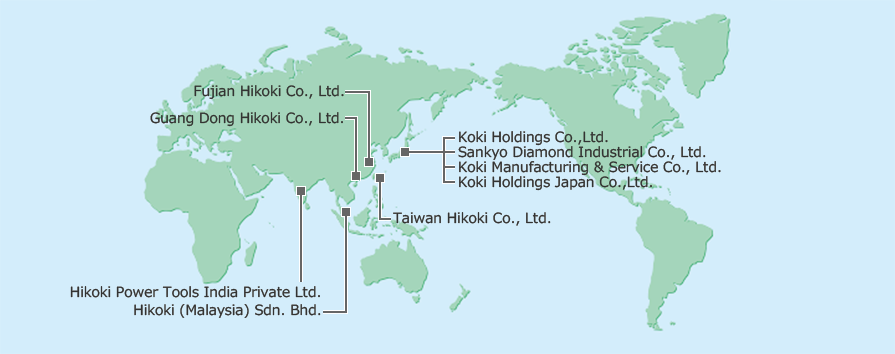

Koki Holdings Co.,Ltd. Sankyo Diamond Industrial Co., Ltd. Koki Manufacturing & Service Co., Ltd. Koki Holdings Japan Co.,Ltd. Fujian Hikoki Co., Ltd. Guang Dong Hikoki Co., Ltd. Taiwan Hikoki Co., Ltd. Hikoki (Malaysia) Sdn. Bhd. Hikoki Power Tools India Private Ltd. |

ISO 14001 Environmental Management System Certification Status

We obtained ISO 14001 Environmental Management System certification in Japan in 1996. Today, our domestic sites in total, three in total including one group company site, are managed and operated in line with this environmental standard. The four plants in China and other Asian countries also achieved certification individually and are managed and operated accordingly.

Scope of Certification

| Company name | Certification organization |

|---|---|

| Koki Holdings Co., Ltd. Katsuta Plant, Sawa Plant | JACO: Japan Audit and Certification Organization for Environment and Quality |

| Sankyo Diamond Industrial Co., Ltd. nabari Plant | |

| Hikoki (Malaysia) Sdn. Bhd. | BVC: Bureau Veritas Certification |

| Guang Dong Hikoki Co., Ltd. | BSI: British Standards Institution |

| Taiwan Hikoki Co., Ltd. | |

| Fujian Hikoki Co., Ltd. |

Internal Environmental Audits

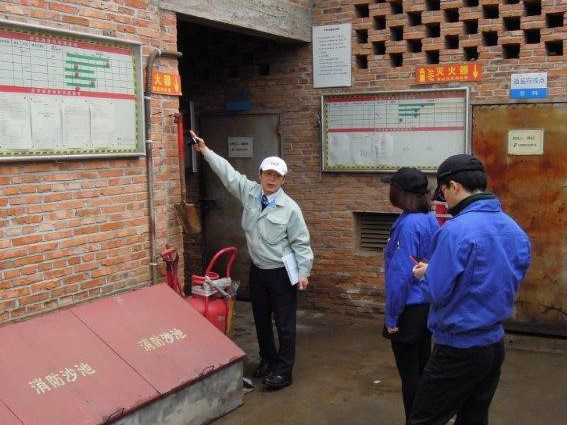

Internal environmental auditors are professionally trained and certified personnel who carry out internal audits of the environmental protection activities of all divisions. All problems detected during audits are remedied to improve environmental management. In addition, we provide auditors with ongoing training and education to maintain and improve audit system performance. The five overseas plants are periodically audited by the Consolidated Environment Promotion Section to ensure consistency of environmental protection activities with global standards.

-

Internal environmental audits: examining documents

Internal environmental audits of overseas plants:

site visit

Environmental Risk Management System (Domestic Factories)

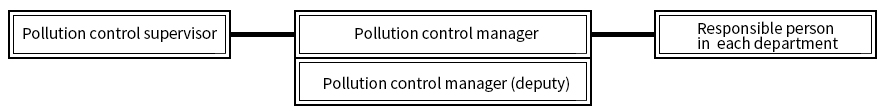

To address environmental risks, we’ve established an organization meeting the requirements of the Law concerning the Improvement of Pollution Prevention Systems in Specific Factories. In addition, each department conducts an emergency drill once a year.

(1) Organization under the Law concerning the Improvement of Pollution Prevention Systems in Specific Factories

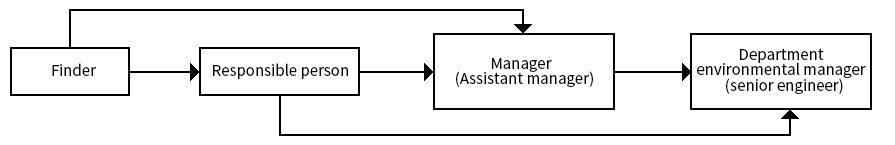

(2) Emergency contact system

(3) Emergency drill

-

Emergency drill in Katsuta Plant

Emergency drill in Sawa Plant